Golden Kupol

for National Geographic Russia, 2014

The Golden mine Kupol is situated in the remote area at the far end of Eastern Siberia in the Russian district of Chukotka.

It is accessible for workers only by air with a two hours flight from Magadan. Between November and April, low temperatures allow for a 350 km ice road across tundra leading to the port of Pevek. This is the main way for industrial logistics and supply delivery.

After South Africa, this region of Siberia is thought to have the biggest gold reserves in the world.

Before the Canadian company Kinross Gold began mining Kupol in 2008 (the construction of the site started in 2005), these gold supplies were worked by inmates of Stalin’s camps in the 30s.

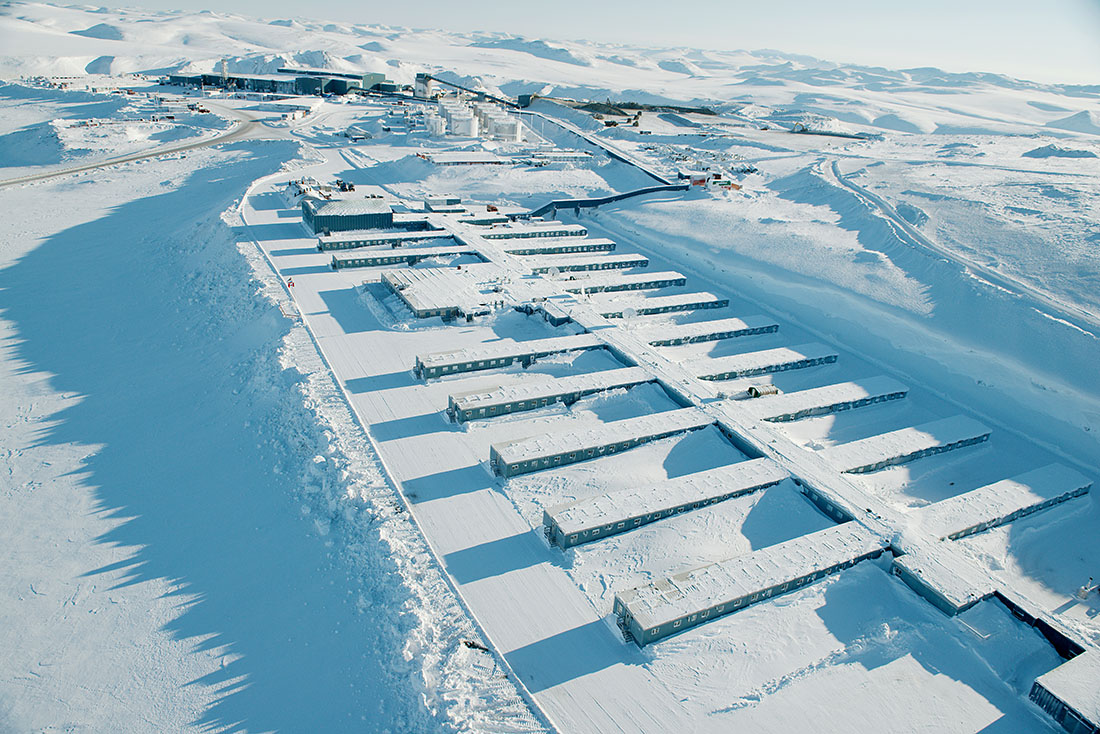

Nowadays, this mine is the modernist in the world located in such severe conditions and isolation. It looks like a set of science fiction films. In every field, advanced technologies are integrated. Remotely operated drills work the deepest recesses of the mine to minimize the risk of workers. Living quarters look like a space station with its long corridor and sleeping wings on its both sides. They are ultramodern. Sleeping departments are quiet and isolated from noisy areas, while the corridor is filled with animation and recreation spaces like gym, billiard, Ping-Pong, library, video halls, praying rooms, tearooms and a joyful café with local Rock band formed by workers. In addition, there is an experimental hydro-culture greenhouse that provides around 25 kg of fresh salad every day and integrates the local population for jobs. A heated 900 meters arctic tunnel leads workers to the factory and administration building when temperatures can drop down to -50 C.

Mines are maintained by an international team. Russian and Ukrainian represent 75% of employers while the rest of workers come from all over the world – Canada, Germany, Brazil, Chile, Hungary. A working period extends for 2 months with a 12 hours working day and followed by 2 months holidays.

Kinross pays a lot of attention to ecology. The company tries to develop different ways of waste recycling, as for example the used oil from mine machines is utilized for the heating system. It is the first site in Russia that got the «Certificate of the International Cyanide Management Code».